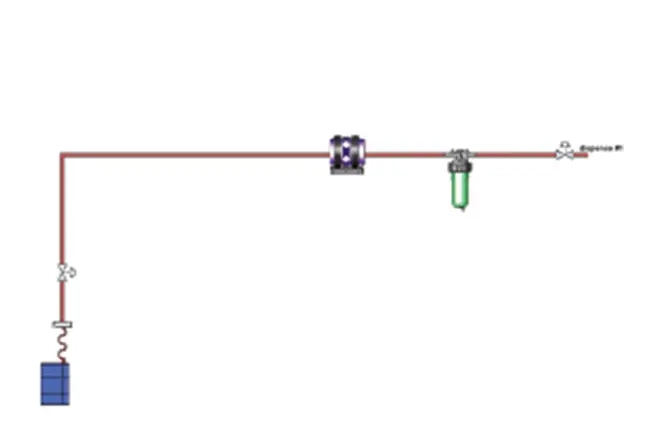

MEGA® Flow S: Raw slurry on request.

MEGA® Flow S supplies the SBD system with raw slurry from two drums. When the raw slurry from one drum is used up, the system switches to the second drum.

Upon request from the SBD system, the contents of a drum circulate through the slurry supply loop to the host until the request is met. Manual modulation of a multi-turn flow choke valve located in the slurry loop return line complements the feed subsystem by maintaining proper back pressure and flow to the mixing system.

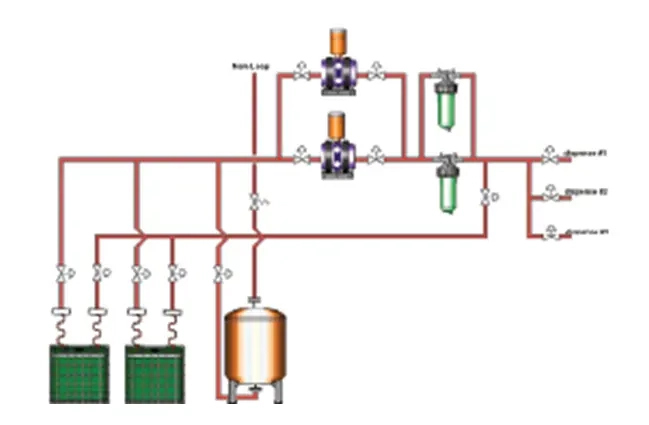

Raw slurry in the drums is independently circulated through the host system. The recirculation function uses one drum while the dispense loop dispenses material from the other drum. Timer setpoints indicate the tumbling time and the time between tumbling events.

Once the system is online and the online tank feeds the SBD system, MEGA® Flow S will circulate continuously. When the SBD system needs more slurry, it draws that slurry from this continuous circulation.

The system at a glance

• Allen-Bradley VersaView touchscreen interface. Used to control and monitor

• A pair of 1” double diaphragm pumps standard

• Automatic flush/clean function

• Cabinet exhaust monitoring and alarm

• Generates humidified N2 for wrapping drums/IBCs