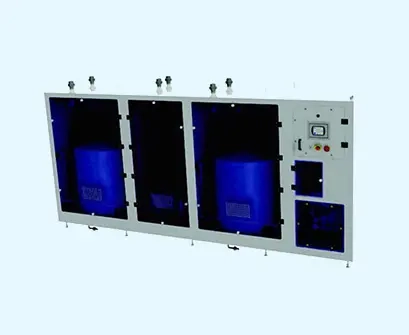

Slurry supply systems: Highest performance, highest standards.

KINETICS Slurry Supply Systems are critical to the success of leading microelectronics companies worldwide. The focus is on the ability to meet tight deadlines while still maintaining high standards.

Through accurate design and agile manufacturing, KINETICS supports today's most demanding chemical mechanical planarization (CMP) processes. The key is planning for expected anomalies such as material variations, operating conditions and personnel monitoring the process.

We benefit from KINETICS' extensive experience in the development and delivery of high-precision slurry systems. Our systems deliver pre-mixed slurry material or mix and dispense extremely challenging slurries. This includes highly critical oxide, tungsten, polysilicon, STI and copper CMP slurry processes.