Solutions for microelectronics and semiconductor technology.

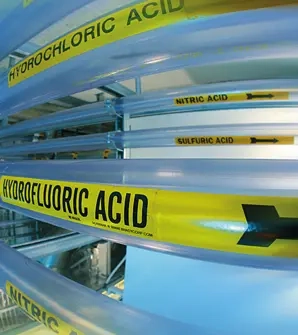

And for biopharma, research labs, and many others.

As one of the world's leading suppliers for the planning and implementation of systems for the supply of clean media, we are at home in a wide variety of industries. Over the past decades, we have implemented many challenging projects together with our customers, including complex process piping systems for the manufacturing and biopharmaceutical industries as well as reliable systems for the generation, treatment and distribution of high-purity gases, chemicals, water and slurries for the semiconductor and photovoltaic industries . Our customers also include data centers, hospitals, research laboratories, central supply systems and commercial buildings.