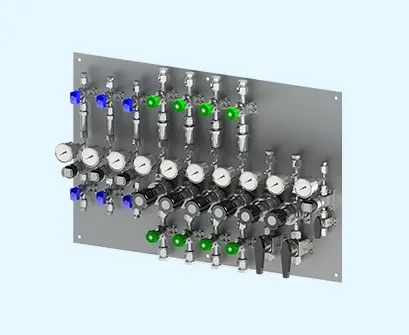

Gas distribution systems: Manual, semi-automatic, automatic.

KINETICS gas distribution systems are used in the semiconductor and solar industries around the world. The systems are designed for the specific requirements of the gas and fabrication process for manual, semi-automated or fully automatic operation.

High volume standardized gas distribution systems are also available for the manufacture of 200mm and 300mm wafers as well as for the manufacture of thin film and silicon photovoltaics. All of our systems are documented in detail to ensure quality and consistency.

KINETICS designs and manufactures gas cleaning and LPG dispensing systems to strict quality guidelines to meet customer specific requirements. All KINETICS gas systems achieve uptimes in excess of 99.999%.