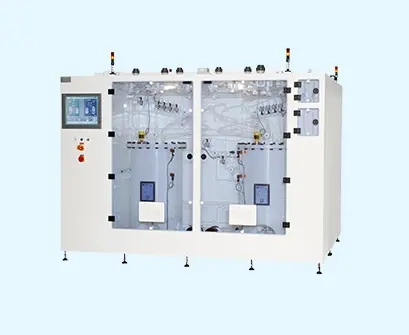

Chemical supply and dosing systems.

With more than 1,500 process media systems installed worldwide, KINETICS is a leading provider of system solutions for chemical supply systems.

Our modular chemical dosing solutions cover a wide range of process applications. Since the modules are configurable, they are suitable for all needs, from new installation to replacement to system upgrade.

We combine powerful, productive dosing technology with ergonomic service features and a wide range of flow and pressure options to deliver tailor-made chemical dosing equipment for a wide range of applications.